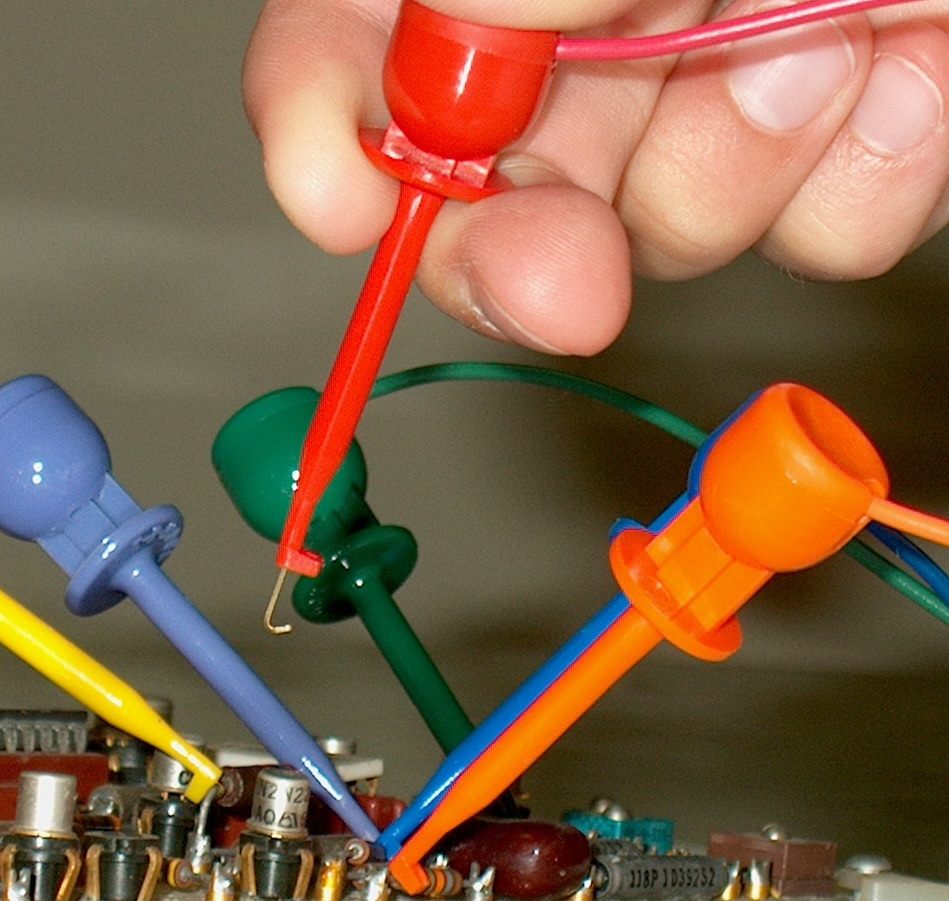

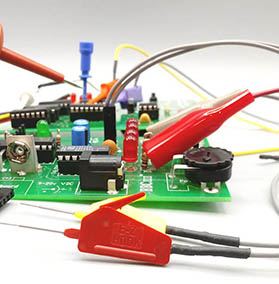

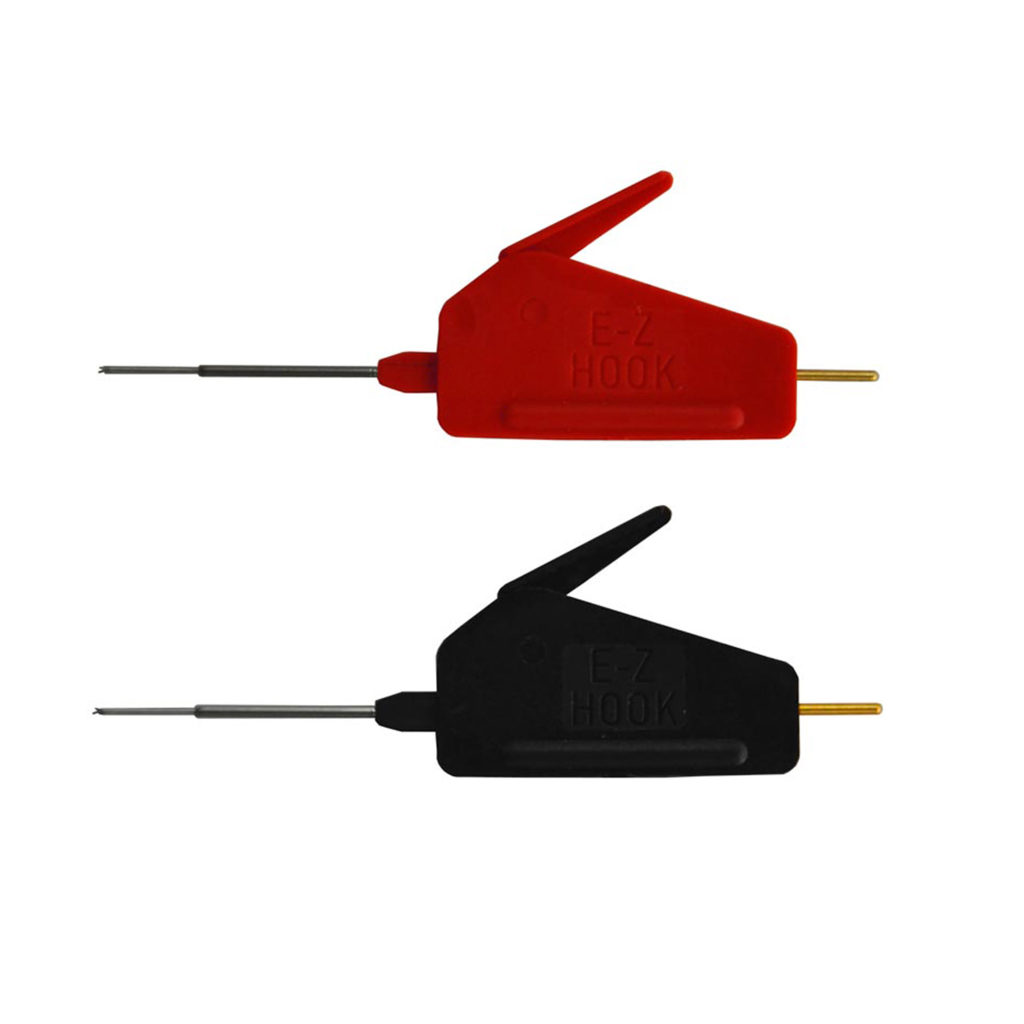

Test hooks are designed to fit over electrical components in a variety of applications to test electrical current, temperature, voltage, and more. In addition, some hooks are specifically designed with a piercing needle to bypass wire insulation and directly connect to a wire’s conductor. In this blog, a general overview of test hook features and construction will be reviewed. E-Z-Hook offers hundreds of test hook and test lead combinations with various wire gauges, wire insulation (PVC, teflon, silicone, rubber), coil cord, breakout cable assemblies, and more. E-Z-Hook’s connectors can be combined in multiple ways to produce your required test lead solution. A commonly sought after feature when purchasing test hooks is a single piercing needle on the contact blade of the hook. This allows users to test electrical measurements without having to reach the end of wires in hard to reach places. Test hooks generally connect to wire via crimp or solder connection, while some have additional contact points (commonly a banana socket/jack), or even both wire attachment and additional adapter capabilities on one hook. Still others are standalone adapters with no permanent wire connection.

Applications / Connect To

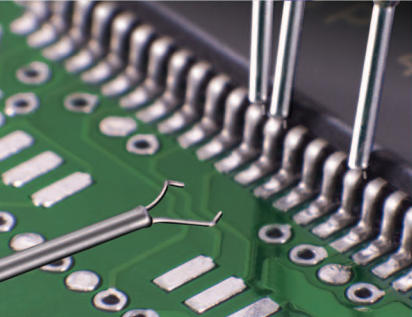

- Circuit Boards & Breadboards

- IC Test Clips

- Surface Mount Chips / Devices

- QFP & DIP & PQEP Packages

- Wire Wrap Terminals

- Hook-Up Wires

- PC Board, Wire Wrapped Pins

- Wire & Test Lead

Industry Solutions

Electrical, Energy, Technicians

Automotive

Education, Robotics, STEM

Medical

Aerospace

Defense

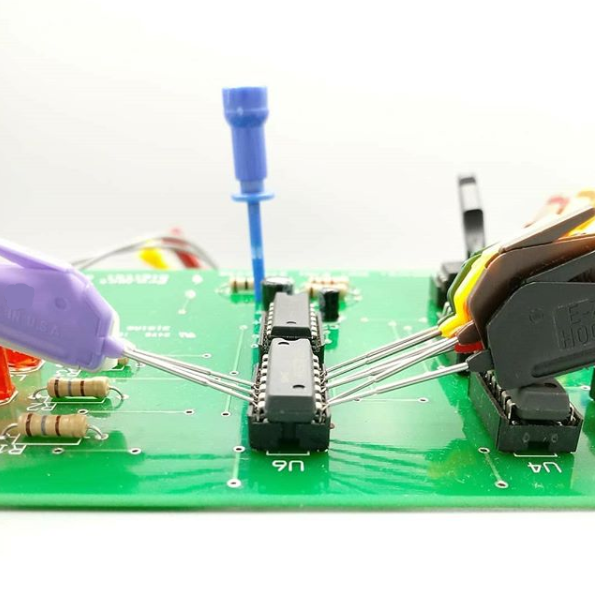

Test hooks are popular components across various industries for prototyping, diagnostic testing, safety testing, analysis, trouble shooting and more. Some examples of our test hooks currently being used in specific industry applications include: automotive (engine, battery, braking systems, sensors, control signals/modules), electrical/energy (lighting, fuse boxes, circuit boards, generators, battery cabinets, electrical systems, air conditioning), aerospace (battery servicing, switches, test terminals and termination points), defense (bomb detection shunt devices), medical (monitoring systems), and education (research & development labs, prototypes). In industry specialized fields, many of our product solutions are custom, however, we have launched a collection of standard products specifically created to meet the market needs. For further assistance beyond our product offerings online, contact our engineering department for further custom solutions.

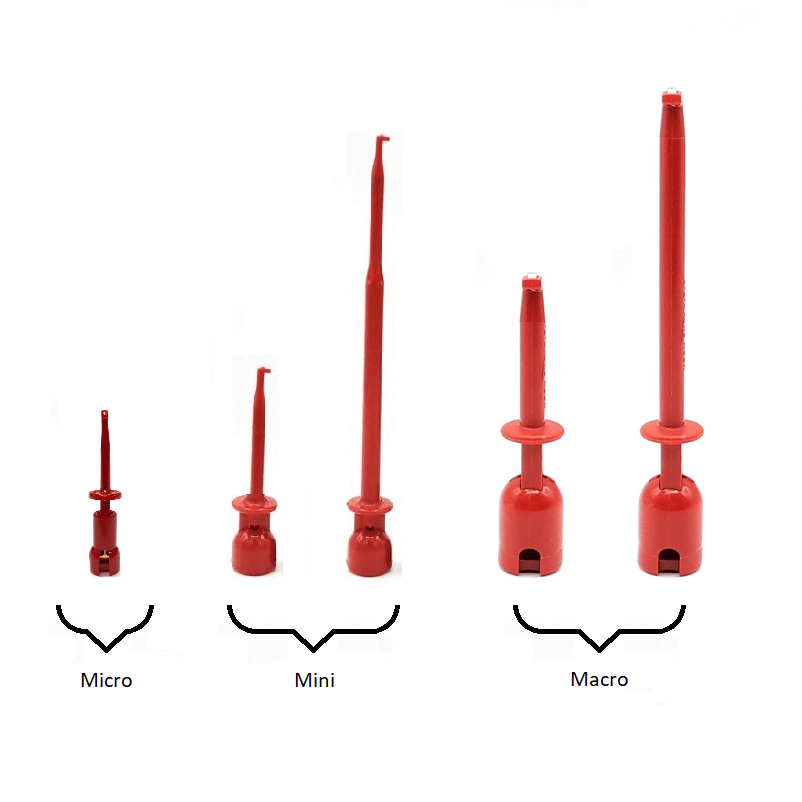

Hook Sizes & Applications

Smallest (Micro)

Designed for use with surface mount devices or where connection point space is limited – especially for narrow test contact areas. An ultra-thin blade and housing allows connector stacking and easier access. Essential for use where weight and leverage may damage components. Its lightweight body (less than 1 gram) and hypo-action easily allows for direct hook-up to delicate wires and components. Best sellers include the X2015, XM, XKM, P25, and XEP.

Large (Macro)

Fits over components up to 0.14 inches (3.56 mm) or 0.35 inches ( mm)

E-Z-Hook Standard Hooks

Size & Length: three size categories (micro, mini, macro) and two lengths (short or long).

Blade Bend : square bend (“U” shape) or rectangular bend (“L” shape). The standard hooks feature a square style hook bend. For unique hooks, a variety of hook bend are utilized like the duel blade grabbers or v-grooved piercing contacts.

Modified Hook Options: modified models include non-magnetic, stainless-steel or copper blade materials, rectangular blade shape tip, insulation-piercing contact blade, and larger wire exit hole accommodations.

Copper Contact Blade: provides greater current capacity

Stainless Steel Contact Blade: for sterile enviroments

Rectangular Tip Blade: to fit over larger components

Non-Magnetic Blades: for non-magnetic testing environments

The standard material used for the contact blades is gold-plated beryllium copper for micro and mini hooks and nickel-silver for macro-hooks. Also available for some hooks is copper (to provide greater current capacity), stainless-steel (great for sterile environments), nickel-plated steel, music wire. Most hooks are also available non-magnetic.

Special Hook Styles

Micro

These micro-hook adapters connect to square socket patch cords with square pins. An exception is the XEP insulation-piercing hook, which connects to pin plugs, or the XG, which is soldered to wire and the tip is inserted into PC board holes.

Mini

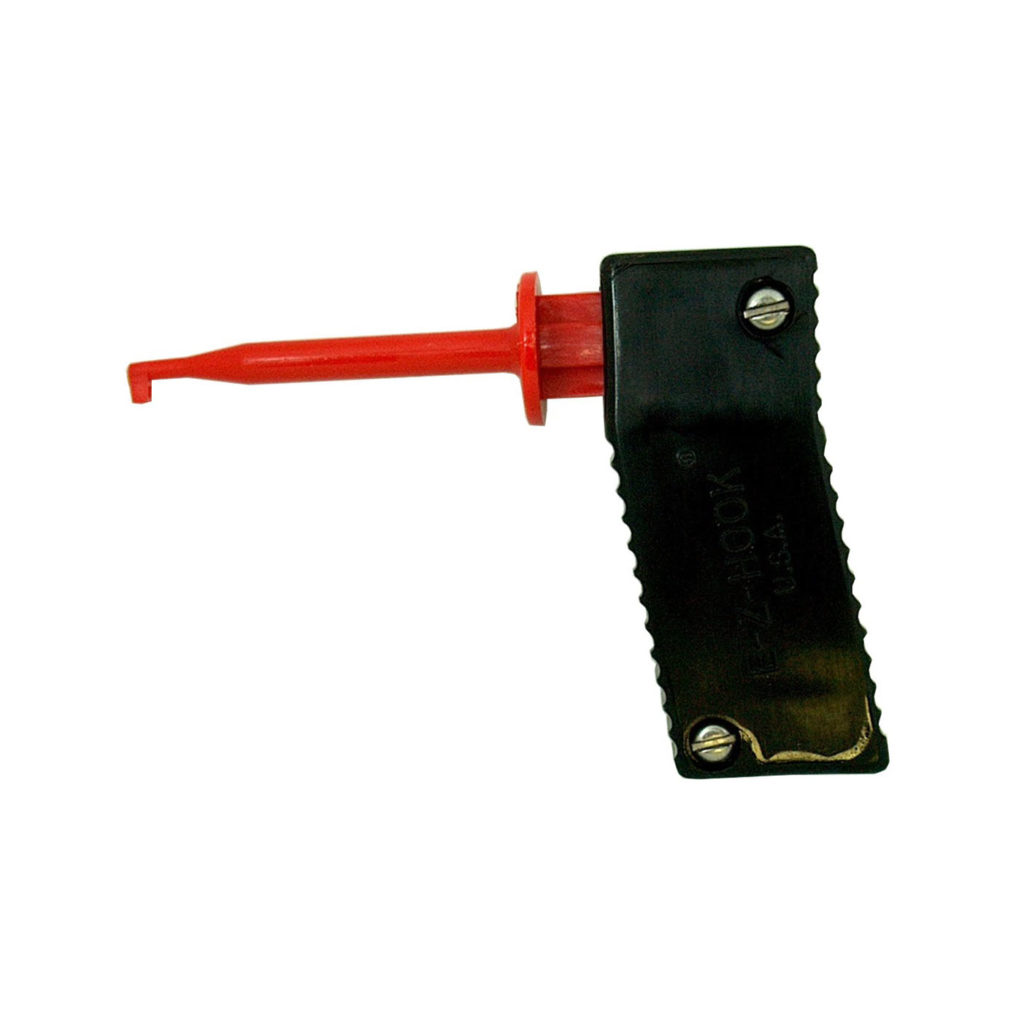

These mini-hook adapters feature any of our short or long length hooks with a “pistol grip” handle (connecting to either a socket or cable) or a unique plunger (connects to a socket).

Macro

This macro-hook adapter features (2) standard banana sockets on either side of the handle which can also be used by shrouding to test lead wire. The insulation-piercing tip is a favorite of the automotive industry and others accessing wire in hard to reach spots.

Special Features

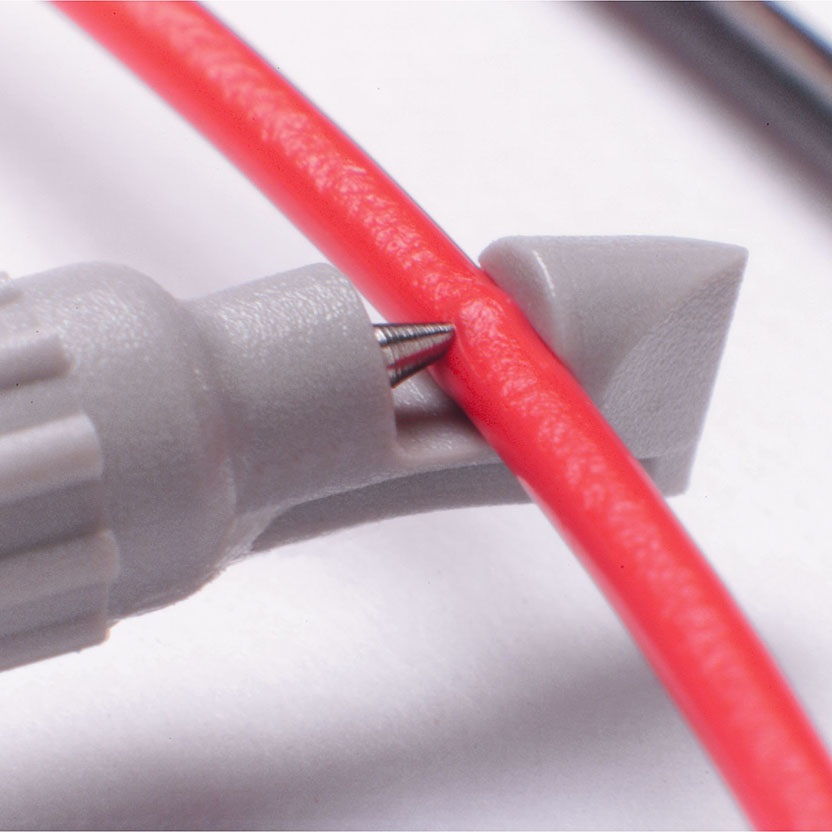

Insulation-Piercing

A commonly chosen feature sought after when purchasing test hooks is a single piercing needle on the contact blade of the hook. This allows users to test electrical measurements without having to reach the end of wires in hard to reach places. A single incision is made into the wire insulation, anywhere on the wire, making instant contact to wire conductor, and upon removal, almost fully self heals, maintaining wire integrity. For a more in-depth look, check out our Guide to Insulation-Piercing Connectors.

Double Hook

Some hooks in the micro-hook product line include two contact blades that act like a miniaturized hand or grabber. Also known as a double/duel/pincer/grabber or hook.

Termination

Test Lead Wire

Cable

Adapters

*Disclaimer: Wire gauges can vary depending on insulation thickness, so if using test lead wire not manufactured by E-Z-Hook, check wire dimensions to ensure they are compatible with our test hooks.

Popular Test Leads

Do you have a local stocking dealer in Portland Oregon area?

Thanks for sharing such great knowledge with us keep updating us more.

Thanks for sharing this tip, really informative and helpful. I’d be using this for my upcoming post. We must all accept it, the value and importance of our role as electrician helping every household be safe I believe this kind of home upgrade is not for DIYs.

Great site! Would include a paragraph at the end explaining what your company does and linking to your products catalogue.