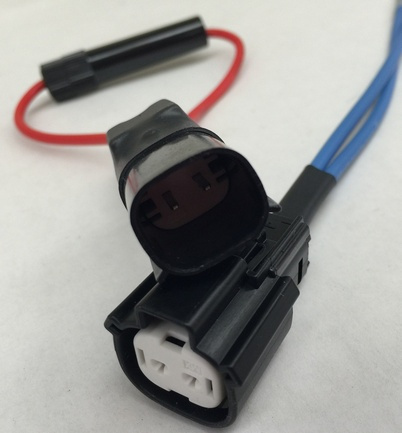

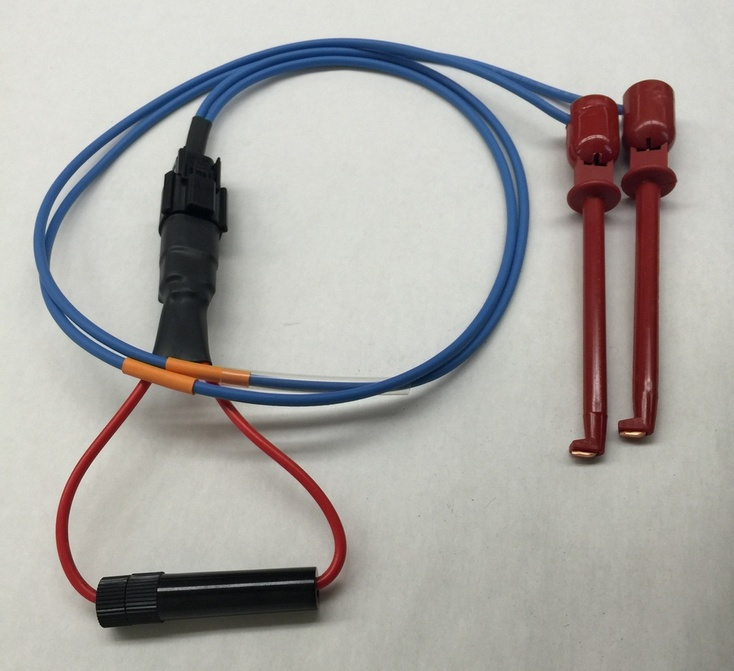

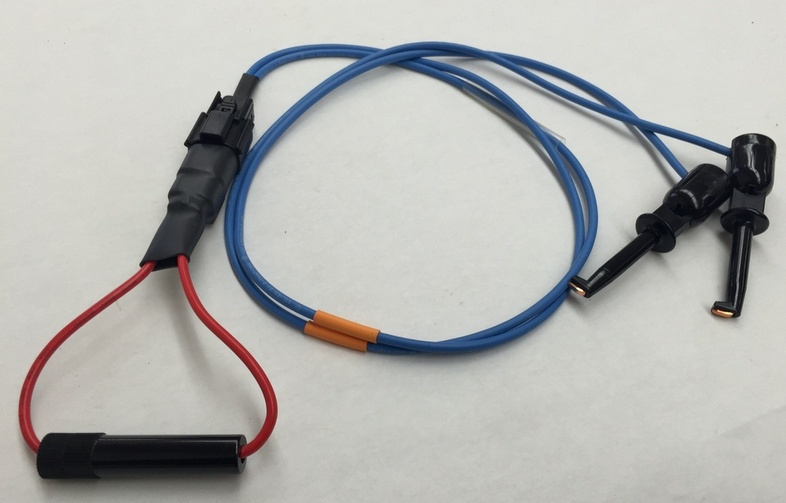

A large multi-state Mid-West power company approached E-Z-Hook to see if we could manufacture custom leads using the copper blade version of our macro-hook test connectors, model XH and XHL. The leads would ultimately be used by plant technicians testing power and required a secure right angle bend on the hooks.

Included in the requirement was the ability to close the power circuit after checking that the hook connection was properly connected. We designed in a “key” concept they requested. It was built into the jumper, allowing the user to close the circuit after the connection was verified as good. Additionally we designed jumpers with a similar fused “key” for further security which was required in some test environments. In the end, E-Z-Hook created four variations of leads, some containing a 3 AMP, 250 Volt fuse.

Let’s make sure everyone’s transparent here; the “large multi-state Mid-West power company” approached YOU with the “key” design to see if you could mass-produce it as it was cheaper than having a technician assemble in their shop. EZ Hook did not design the “key”.

Thanks Kent. It wasn’t our intent to mislead. The original article should have made it clear that we designed IN a “key” (that was purchased by us, existing in the marketplace). This “key” concept was proposed to us by the company you work for. The lead design and how we applied the “key” concept to the jumper was created and designed by our engineer with input from your company. Our custom products are always made to fit the requirements of our customers with important input from our clients.